CNC Plasma Metal Cutting Nottingham

Precision Metal Cutting Services for Custom Signage, Decorative Art & Manufacturing

Metal Cutting Services

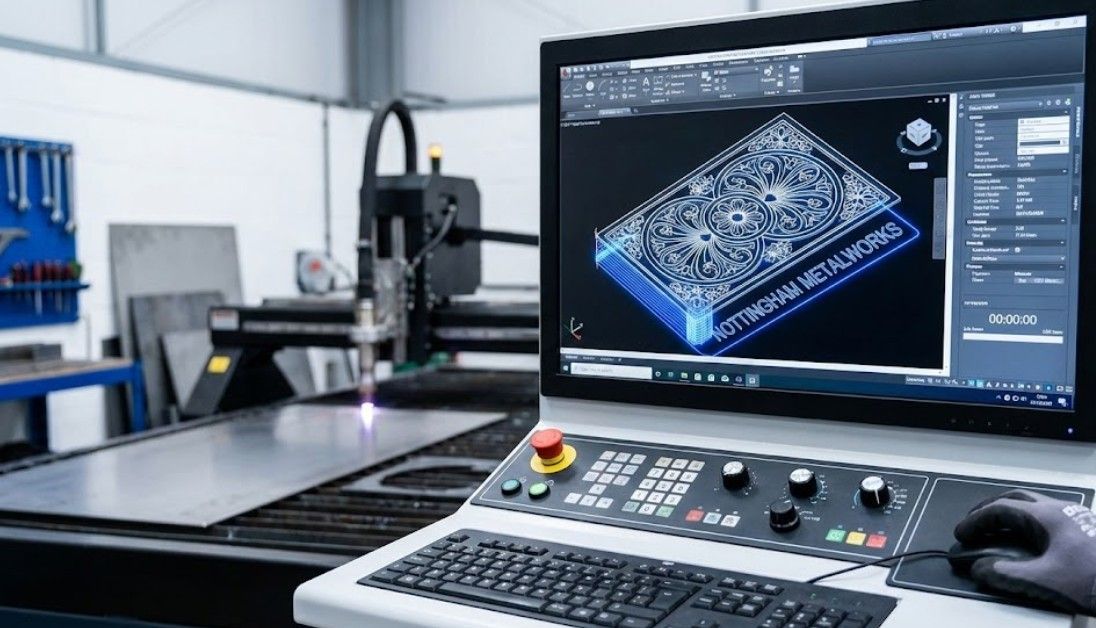

Nottingham Metalworks offers professional CNC plasma cutting services for businesses and individuals across Nottingham and Nottinghamshire. Our computer-controlled plasma cutting technology delivers precision cuts in mild steel, stainless steel, and aluminium for custom signage, decorative metalwork, machine parts, and architectural features.

What is CNC Plasma Cutting?

CNC plasma cutting is an advanced metal fabrication process that uses a computer-controlled plasma torch to cut precise shapes and designs from metal sheets. The technology combines high-temperature plasma (an electrically conductive gas) with CNC (Computer Numerical Control) programming to achieve exceptional accuracy and repeatability.

At Nottingham Metalworks, we use CNC plasma cutting as a core capability within our sheet metal fabrication services, enabling us to create everything from intricate decorative patterns to robust industrial components. Unlike manual cutting methods, CNC plasma cutting follows exact digital specifications, ensuring every piece matches your design requirements precisely.

This process is particularly valuable for projects requiring complex shapes, detailed patterns, or multiple identical components. Whether you need a single bespoke item or a batch of fifty identical parts, our CNC plasma cutting delivers consistent quality and clean edges that minimise finishing work.

The versatility of plasma cutting makes it ideal for commercial signage manufacturers, architects specifying custom metalwork, engineering firms requiring precision parts, automotive enthusiasts restoring or customising vehicles, and homeowners wanting unique decorative features.

HOW CNC PLASMA METAL CUTTING WORKS

The CNC Plasma Cutting Process

Digital Design & Programming

Every CNC plasma cutting project begins with a digital design. We work from your CAD files, technical drawings, or create designs based on your specifications. These designs are converted into CNC programmes that control the plasma torch's movement with millimetre precision. The computer calculates the optimal cutting path, speed, and torch height for your specific material and thickness.

The Plasma Arc

Plasma cutting works by forcing compressed gas through a focused nozzle at extremely high speeds. An electrical arc then turns this gas into plasma—a superheated, electrically conductive state reaching temperatures up to 20,000°C. This plasma jet melts through the metal whilst the high-velocity gas simultaneously blows away the molten material, creating a clean cut edge.

Precision Cutting

The CNC system controls the plasma torch's position and movement across the metal sheet with exceptional accuracy. Unlike handheld plasma cutting, CNC automation eliminates human error and ensures perfectly consistent results. The torch height adjusts automatically to maintain optimal cutting distance, whilst the programmed speed ensures clean cuts without excessive heat distortion.

Material Handling

Metal sheets are secured on our cutting table, and the CNC system executes the programmed design. For complex projects involving multiple cuts or nested parts (multiple pieces cut from a single sheet to minimise waste), the system optimises the cutting sequence for efficiency. Once cutting is complete, parts are removed, and any minimal slag or edge imperfections are cleaned.

Quality Control

Every CNC plasma cut component is inspected to ensure it meets specifications. The precision of CNC cutting means parts typically require minimal finishing, though we offer deburring, grinding, and edge preparation where required before welding or final assembly.

Why Choose CNC Plasma Cutting?

Exceptional Precision & Accuracy

CNC plasma cutting delivers tolerances that manual cutting simply cannot match. The computer-controlled torch follows your design exactly, producing identical results whether cutting one piece or one hundred. This precision is essential for parts that must fit together perfectly or signage requiring crisp, clean lettering.

Complex Shapes & Intricate Designs

From simple rectangles to elaborate decorative patterns, CNC plasma cutting handles designs of any complexity. Intricate logos, detailed architectural screens, complex machine brackets, and artistic metalwork—all are achievable with plasma cutting technology. If you can design it digitally, we can cut it.

Cost-Effective Manufacturing

Plasma cutting offers excellent value, particularly for projects not requiring the ultra-fine tolerances of laser cutting. The process is faster than traditional cutting methods, reducing labour costs. For batch production, CNC automation means no increase in cutting time per piece, making small to medium production runs highly economical.

Versatile Material Compatibility

Our CNC plasma cutting equipment handles mild steel, stainless steel, and aluminium across a range of thicknesses. This versatility means we can manufacture diverse components—from thin decorative panels to thicker structural brackets—using the same process.

Minimal Material Waste

CNC programming optimises part placement on metal sheets, reducing offcut waste. For batch production, parts can be nested efficiently to maximise material usage, lowering your material costs whilst supporting sustainable fabrication practices.

Fast Turnaround Times

Once programmed, CNC plasma cutting is significantly faster than manual cutting or traditional fabrication methods. The automated process means we can complete projects quickly without compromising quality, ideal when you're working to tight deadlines.

Consistent Quality

Every piece cut by our CNC plasma system meets the same high standard. There's no variation between the first and last piece in a batch, ensuring uniform quality across your entire project. This consistency is particularly valuable for commercial applications where brand standards must be maintained.

APPLICATIONS & WHAT WE CAN CREATE

CNC Plasma Cutting Applications

Custom Metal Signage

CNC plasma cutting excels at creating business signage with precise lettering and intricate logos. We fabricate shopfront signs with crisp, clean edges, illuminated sign backing and frameworks, built-up letters and logos, property and building signage, and wayfinding signs for commercial premises. The precision of CNC cutting ensures professional results that represent your brand perfectly. Explore custom metal signage options →

Decorative Metal Art & Screens

Transform spaces with CNC plasma-cut decorative metalwork. Popular applications include intricate privacy screens and room dividers, garden art and sculptural features, architectural panels with custom patterns, decorative gates and fence infills, and feature walls for commercial or residential interiors. The technology allows us to create flowing organic designs or geometric patterns with equal precision. View decorative metal art examples →

Precision Parts & Components

Manufacturing and engineering businesses rely on our CNC plasma cutting for accurate metal components including machine brackets and mounting plates, equipment guards and covers, custom fixtures and fittings, replacement parts for machinery, and prototype components for testing. The consistent accuracy ensures parts fit correctly and function as intended. Learn about precision parts fabrication →

Automotive Components

From classic car restoration to custom builds, CNC plasma cutting creates automotive parts such as chassis brackets and modifications, custom panels and trim pieces, exhaust hangers and mounting brackets, and engine bay components. Precise cutting ensures parts integrate seamlessly with existing vehicle structures. See automotive metalwork services →

Architectural Features

Architects and designers specify CNC plasma-cut elements for building projects including decorative façade panels and cladding, balustrade infills and screens, ventilation grilles with custom patterns, structural brackets and supports, and bespoke architectural details. The technology enables creative freedom whilst maintaining structural requirements.

Discover architectural metalwork →

MATERIALS & SPECIFICATIONS

CNC Plasma Cutting Materials & Capabilities

Mild Steel

Our most commonly requested material for CNC plasma cutting. Ideal for structural components, signage frameworks, brackets, and general fabrication. Available in various thicknesses up to 15 mm. Cost-effective and readily weldable for assembled projects. Requires priming and painting for corrosion protection in outdoor applications.

Stainless Steel

Perfect for applications requiring corrosion resistance or a premium aesthetic. Popular for architectural features, food industry equipment, marine environments, and decorative applications. We cut 304 and 316 grades in thicknesses up to 13mm. Natural finish or polished to your requirements.

Aluminium

Lightweight yet strong, aluminium is excellent for signage, decorative screens, and applications where weight reduction matters. Naturally corrosion-resistant with an attractive finish. Plasma cutting handles aluminium efficiently in thicknesses up to 18 mm.

Cutting Thickness Range

Our CNC plasma cutting equipment accommodates material thicknesses from thin sheet metal through to 20 mm plate, depending on material type. For your specific requirements, contact us to confirm capabilities for your project specifications.

GETTING STARTED WITH CNC PLASMA METAL CUTTING

Request Your CNC Plasma Cutting Quote

Starting your CNC plasma cutting project with Nottingham Metalworks is straightforward. Contact us with your design files (DXF, DWG, or other CAD formats), sketches, or project description. We'll discuss material options, thicknesses, quantities, finishing requirements, and timelines.

We'll provide a detailed, competitive quote with no obligation. Once approved, we programme your design into our CNC system and begin fabrication. Most CNC plasma cutting projects are completed within a few days, with expedited services available for urgent requirements.

Whether you need a single decorative panel or batch production of commercial components, our CNC plasma cutting delivers the precision and quality your project demands. We combine modern technology with traditional craftsmanship, ensuring every cut piece meets our exacting standards.

CNC Plasma Cutting Services in Nottingham

Ready to discuss your CNC plasma cutting project? Contact Nottingham Metalworks today. Request Your Free Quote

Call: 0115 647 6611

We serve Nottingham, Nottinghamshire, and surrounding areas across the East Midlands. From concept through to completion, we'll manufacture your metal components with precision and care.